On 9th February 2022, the Managing Director of 3-D MID, Philipp Bräuer, warmly welcomed the 26 participants to the 5th MID Day. First, Mr. Bräuer introduced the participants to the Research Association 3-D MID and its current research projects. He also reported on the participation of 3-D MID at the LOPEC and electronica trade fairs, at which the Research Association will provide information about its activities and those of its members. At electronica, in addition to the Research Association, the members can also present themselves at the joint booth. Seven members have already registered for the joint booth.

Richard Retallick, Head of Electronics Specialties at MacDermid Alpha, gave the first presentation on “Advanced MID Metallisation Technologies”. He began by introducing MacDermid Alpha as a company. Mr. Retallick then demonstrated the achievements in metallisation of printed circuit boards and IC substrates as well as mouldable and flexible circuits. He also explained the three established MID technologies 2K without palladium additives, 2K with palladium additives and Laser Direct Structuring (LDS). Then the process of external currentless MID Metallisation was described and the innovations in copper metallisation and developments in surface finishes were presented. Finally, he presented the innovative PackagePlate process, a special metallisation solution for the packaging of bare dies. This PackagePlate process enables the integration of electrical circuits directly into the chip package. Afterwards, Mr. Retallick answered the many in-depth questions from the participants.

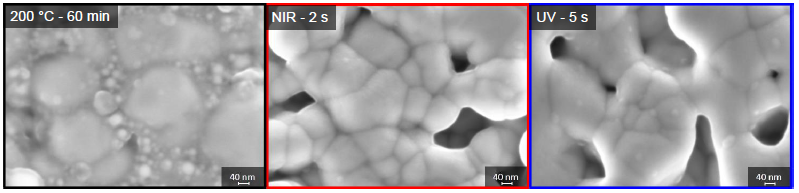

The second presentation was given by Jewgeni Roudenko from TH Nuremberg on the research project AVerdi – Alternative densification processes for inks containing nanoparticles printed with digital printing processes for MID and smart cards. The research team consisted of staff from the Institute of Chemistry, Materials and Product Development at the University of Technology Nuremberg (OHM-CMP) and the Chair of Factory Automation and Production Systems (FAPS) at FAU Erlangen-Nuremberg. The team aimed to reduce the drying and sintering time of digitally printed silver nanoparticle inks by NIR and/or UV irradiation on flexible substrates and injection-moulded substrates and to create a guide to help users select the appropriate printing and sintering technology.

- Significantly shortening the sintering time with comparable or better electrical conductivity and adhesion.

- Achieving high electrical conductivity on thermally resistant substrates

The results show that the thermal properties of silver inks are crucial to achieve faster and better sintering, especially on substrates such as PET

Our members can find the presentations of all past MID Days here.

The next MID Day will take place on 11 May 2022. More information about the next MID Day will be available here soon.

Further dates of the MID Days and other events can be found in the calendar of events.