Intelligent shaft seals using 3D MID sensor integration [SmartSeal]

The Research Association 3-D MID is still looking for companies to accompany the project. If you are interested, please contact the office via phone (+49 911 5302-9100) or E-Mail (info@3d-mid.de). E-Mail to office

Description

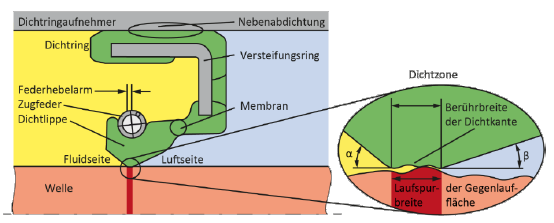

In many technical applications, rotating axles and shafts must be sealed – for example in vehicle transmissions, washing machines or conveyor systems. Radial shaft seals (RWDR) made of elastomer are often used for this purpose. The RWDR presses against the axle/shaft with the so-called sealing edge, which creates the sealing contact. Due to the relative movement between the sealing edge and the shaft, frictional heat is generated in the sealing contact, which leads to a temperature increase in the contact area. A frequent cause of failure of RWDR is thermal damage, in which the sealing edge hardens and/or oil carbon is deposited on it. Both can lead to failure of the sealing system and thus the entire machine. In order to avoid thermal damage, not only the design of the sealing point but also the conditions prevailing during operation are decisive.

Thermal damage and failure can be avoided by reacting to critical operating situations during operation. For this purpose, the temperature at the sealing edge must be known. Due to many – partly mutually coupled – influencing factors on the temperature, it cannot be calculated analytically, but must be measured.

Figure 1: Radial shaft seal; Source: University Stuttgart, Institut for Machine Elements (IMA) – Sealing technology

Research objective

- In the research project, a sensor is to be integrated into shaft sleeves, which serve as the mating surface of radial shaft seals, by means of 3D-MID, which measures the temperature exactly under the sealing contact of the sealing edge without changing the sealing behaviour. A step-by-step functional verification is to be carried out with prototypes that build on each other.

- With the help of CHT simulation and verification by thermography, the exact temperature is to be determined under a wide range of operating conditions and compared with the measured values from objective 1. The evaluation logic of the sensor should “correct” the measured temperature and transmit the exact temperature in sealing contact with a common radio standard.

Figure 2: Temperature sensor for sealing systems; Source: University Stuttgart, Institut for Machine Elements (IMA) – Sealing technology

Benefits and economic significance for SMEs

Companies – and in particular SMEs from various sectors – benefit from the research results.

- Companies, especially SMEs from the MID sector, receive application-oriented, pre-competitive research results that can then be transferred by the companies into new, innovative products – namely sealing components with temperature sensors – and thus strengthen their competitiveness. Through the cooperation of the two research centres, MID technology is being prepared for use in sealing technology across all industries. The knowledge gained in the research project using the example of the radial shaft seal can then be transferred to other dynamic sealing systems.

- Companies from the automotive, mechanical engineering, plant construction and related industries benefit when they use sealing systems equipped with temperature sensors. This makes their products smarter and allows them to react to the condition of sealing systems during operation. This means that failures – both at the level of the seals and at the level of the entire machine/plant – and their ecological and economic damage can be reduced and longer and more predictable service lives can be realised. This improves the products and strengthens the competitiveness of the companies.